The support site and this forum really is all you need to get proficient with the software. Get proficient with simple single sided jobs before you start worrying about jobs bigger than your table and double sided. I think you're worrying yourself into a hole over things that you will pick up really quickly once you start using your machine in anger and you're getting a bit ahead of yourself as well. A lot of people start off with double sided tape and then start screwing things down and never go any further than that. Look at this project for simple double sided machining instructions - Ĥ. Haven't done it myself but there are lots of threads about it. The machine will cut the project square even if the material is slightly out of line.Ģ. Good old fashioned measuring tape! If you're cutting the project out of a large piece of material then it doesn't really matter if it's not exactly square. What would be best is if there was an experienced VCarve Pro user close to me and I could just spend a day with them in their shop watching and asking questions as well as looking at projects that I may want to do and ask them what their approach would be.ġ.

#Vectric vcarve pro 8 tutorials trial

I know that I will learn a lot from trial and error, but the VCarve Pro for Dummies book would answer these questions and many more that the beginning user wonders about. Hmmmm.Īnd these kinds of things just continue to knock around in my head. I've seen inlaid tracks on some machines, other say just screw down to your spoil board. I plan on 3/4" MDF with another piece (3/4" or 1/2" MDF spoil board on top of that. I haven't installed the bed on my machine yet. If you wanted to carve on the top and bottom of a piece, how do you insure, when you flip the piece over that the cuts on the second side are in the correct place relative to the top cuts? For instance, a wooden lid that had a design carved in the top side and a name in the bottom side.Ĥ. If you want to do a piece longer than your bed (I think about it as 2 tiles, end for end) how do you insure that when you move the piece thru your machine that the cutting resumes exactly at the right place? Example, my bed is 24" and I want to carve text into a board that is 39" long.ģ. How do you insure that the edge of your project is parallel with the X axis of your CNC machine?Ģ. This are a few of the things I'm thinking of while getting the shop ready.ġ.

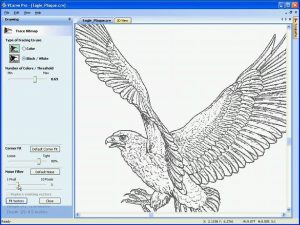

So I'm wondering, is there a VCarve Pro for Dummies book? While I'm sure that if I read every single post on this forum and studied all of the Vectric tutorials, I would find an answer to every single question, that's not gonna happen. While setting up my shop, my mind is racing thinking about all the posts I've read on this forum, the many different types of work people are doing and my very limited knowledge of it all.

0 kommentar(er)

0 kommentar(er)